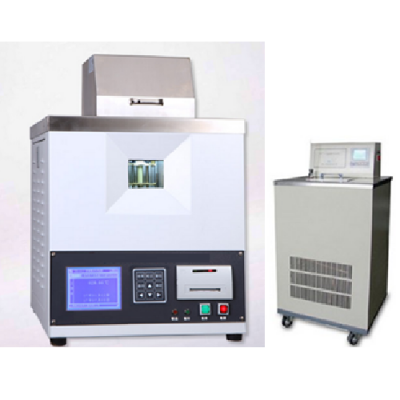

Bituminous Mixtures Vibration Wheel Crushed Machine

Product ID:HW- SYD-0703-2

This instrument is designed and manufactured in accordance with the requirements of T0703-2011 "Method for Making Asphalt Mixture Test Pieces (Wheel-Rolling Method)" in the People's Republic of China industry standard JTG E20-2011 "Highway Engineering Asphalt and Asphalt Mixture Test Regulations". It is mainly used for rolling and forming the asphalt mixture sample before the rutting test. This test piece can be used for testing the physical and mechanical properties of asphalt mixtures, such as the high-temperature anti-rutting ability of asphalt mixtures, and the high-temperature stability of the asphalt mixture ratio design.

This instrument is an automated instrument that integrates mechanical, computer, electrical, and air pressure control. Compared with similar products, it has the characteristics of small size, high degree of automation, strong functions, and convenient operation. It is an ideal instrument for asphalt mixture rolling and forming.

I. Main technical features

1. With color touch screen, the operation of the instrument, data display and parameter input can be completed on the touch screen.

2. The display screen shows the compacter temperature, compacting times and other parameters in real time, and has the function of self diagnosis.

3. It has the function of real-time display and inspection of compacter pressure to ensure that the test is carried out under the correct compacter pressure.

4. It has the automatic alarm function when the compacter pressure exceeds 3% of the set pressure to inform the operator to respond accordingly.

5. With advanced air pressure control technology, the compacter pressure can be set and adjusted in the range of (0 ~ 20) kn.

6. The height of the test mold can be set and adjusted in the range of (30 ~ 100) mm.

7. The fixture structure of test model is advanced, safe and reliable, and easy to use.

8. There are two processes for compacting forming specimens, each of which can be completed automatically, reducing the operation steps and basically realize one-click-to-complete.

9. The front left and right opening safety protection door is designed to ensure the safety of the operator.

10. With the function of pressure calibration, user can calibrate the pressure of the compacter on the instrument.

II. Main technical specifications

1. Power supply: AC380V, 50Hz, 3.0kW (three-phase four-wire system, the yellow-green line is the neutral line)

2. Air Supply: Pressure: 0.7Mpa, Exhaust volume: 40L/min

3. The mill pinion specification: radius is 500mm, width is 300mm

4. The mill pinion compaction load control range :(200~700)/cm

(Can be adjusted arbitrarily, adjusted to 300 N/㎝ before leaving the factory)

5. The mill pinion compaction load compacting accuracy: ±3N/cm

6. The mill pinion temperature compacting range : ambient temperature ~200℃

7. The mill pinion temperature compacting accuracy :+5℃

8. Compacting speed: 6 times / min ± 0.5 times / min

9. The compaction times : can be set in the software, default value: P1: 4times;P2: 12times

INQUIRY

CATEGORIES

- Coal Testing

- Petroleum Testing

- Muffle Furnace

- Highway Instruments

- Direct Reading Spectrometer

- Abbe & Auto Refractometer

- Agricultural Instruments

- Autoclave/Sterilizer

- Weighting Balance & Scales

- Safety Cabinet & Clean Bench

- Carbon & Sulfur Analyzer

- Centrifuge

- Clinical Instruments

- Colorimeter & Color Light Box

- Dehumidifier & Humidifier

- Electrolyte Analyzer

- Electrophoresis Cell

- Freeze Dryer

- Gas Generator

- Gene Test

- Heating & Drying Oven

- Pathology Instruments

- Ice Maker

- ICP Spectrometers

- Incubators

- Infrared Thermometer

- Freezer & Refrigeration Products

- Liquid Nitrogen Container

- Biological Microscope

- Microwave Digestion & Extraction

- Mixer & Homogenizer

- Mixer & Shaker

- Moisture Analyzer

- Moisture Tester

- Oil-in-Water Analyzer

- Pack & Paper Testing

- Automotive teaching model

- Particle Counter

- Plastic Testing

- Particle Size Analyzer

- Polarimeter & Saccharimeter

- Rotary Evaporator

- Sampling Instruments

- Small Instruments

- Spectrophotometer

- Water Purifier

- Water quality detector

- XRF

- Water Testing

- AUTOMATIC TITRATORS

- Thermal Analysis

- Automatic Kjeldahl Analyzer

- TOC Analyzer

- Universal Testing Machine

- Price List of Reagents

- Fluorescence Spectrometer

- NIR Spectrophotometer

LATEST NEWS

CONTACT US

Contact: Harry

Phone: 00852-82283663

E-mail: info@lab-kits.com

Add: ROOM 1, 16F, EMPRESS PLAZA, 17-19 CHATHAM ROAD, TSIM SHA TSUI, KOWLOON, HONG KONG