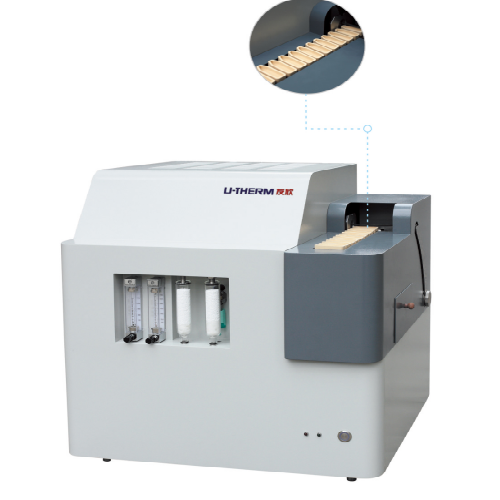

Automatic IR Sulfur Analyzer

Product ID:YX-DL8802

Application area

It is applicable in the industry such as electrical power, coal, commerce inspection, environment protection, metallurgy, paper making, petrochemical, earth probe, and the research institution or quality inspecting organization to measure the total sulfur content in the materials of coal, cinder, coke, catalyst, minerals, rock, and petrochemicals.

4. Technical parameters

l Measurement range: 0.01% ~ 40% (can be expanded according to user requirements)

l Test method: infrared spectrum absorption method

l Sulfur measurement resolution: 0.001%

l Working furnace temperature: 1300 ℃

l Temperature control accuracy: ± 1 ℃

l Sample Weight: 300 ± 10mg (coal, coke), 100 ± 10mg (petroleum products)

l Sample sending method: automatic sample sending, discarding sample

l Number of samples: 12 / batch, test samples can be added / replaced

l Single sample analysis time: about 2min

l Accuracy: In accordance with GB / T25214-2010 "Determination of total sulfur in coal by infrared spectroscopy"

l Power: ≤4kW

l Working power: AC220V ± 22V / 50Hz

l Dimensions (mm): 670 × 580 × 720

l Overall weight (kg): 87

5. Features

l Automatic sample loading, testing, and discarding until the testing results available; the advanced feeding facility was used (Patent No 2013200307699)

l The ultra-low draft IR cell was used to make sure the good reliability and high precision of the instrument.

l The special gas dilution device was used to achieve expanding the testing range without replacing the IR cell.

l The fault-tolerant diagnostics function was built inside the software, thus it could judge where the problem is in case any problem happens.

l The highest quality heater and burning tube were used to make sure the long life spam of the heating system.

l The highest quality materials were used in gas circuit to make sure there is no leakage, thus the precision could be assured.

l The feeding pipe and feeding pole were separated, so their life spam would be longer while the maintenance is easier.

l Software could be linked to lab management system, the testing data could be uploaded and copied online.

6. Configuration

No | Name | Specification | CAT No | QTY | Unit |

1 | Testing Machine | 1 | Unit | ||

2 | Instruction Manual | 1 | PC | ||

3 | Software CD | 1 | PC | ||

6 | Sampling Rod | 1 | PC | ||

7 | Combustion Tube | 1 | PC | ||

8 | Silicon Carbon Tube | 1 | PC | ||

9 | Drying Tube | 2 | PC | ||

10 | Thermocouple | 1 | PC | ||

11 | / | ||||

12 | Fluorocarbon Resin soft Tube | 1 | Meter | ||

13 | Small O-ring | 26×3.55 (Fluorocarbon Resin) | 2 | PC | |

14 | Small O-ring | 8×1.8 (Fluorocarbon Resin) | 2 | PC | |

15 | Crucible | 40 | PC | ||

16 | PU Gas Pipe (PU0604) | 2 | Meter | ||

17 | PU Gas Pipe (PU0806) | 4 | Meter | ||

18 | Coal Reference | Standard Coal Sample for Calibration | 3 | Bottle | |

19 | Heating power cable | 20A(connect with transformer) | 1 | Set | |

20 | Serial Cable | 1 | PC | ||

21 | 3-pin power cable | 10A/250VAC | 1 | PC | |

22 | Fuse | φ5/20(5.0A) | 3 | PC | |

23 | Power transformer | 1 | PC | ||

24 | Decompression valve | For oxygen | 1 | PC | |

25 | Multi-function Connection Box | For cable connection | 1 | PC |

INQUIRY

CATEGORIES

- Coal Testing

- Petroleum Testing

- Muffle Furnace

- Highway Instruments

- Direct Reading Spectrometer

- Abbe & Auto Refractometer

- Agricultural Instruments

- Autoclave/Sterilizer

- Weighting Balance & Scales

- Safety Cabinet & Clean Bench

- Carbon & Sulfur Analyzer

- Centrifuge

- Clinical Instruments

- Colorimeter & Color Light Box

- Dehumidifier & Humidifier

- Electrolyte Analyzer

- Electrophoresis Cell

- Freeze Dryer

- Gas Generator

- Gene Test

- Heating & Drying Oven

- Pathology Instruments

- Ice Maker

- ICP Spectrometers

- Incubators

- Infrared Thermometer

- Freezer & Refrigeration Products

- Liquid Nitrogen Container

- Biological Microscope

- Microwave Digestion & Extraction

- Mixer & Homogenizer

- Mixer & Shaker

- Moisture Analyzer

- Moisture Tester

- Oil-in-Water Analyzer

- Pack & Paper Testing

- Automotive teaching model

- Particle Counter

- Plastic Testing

- Particle Size Analyzer

- Polarimeter & Saccharimeter

- Rotary Evaporator

- Sampling Instruments

- Small Instruments

- Spectrophotometer

- Water Purifier

- Water quality detector

- XRF

- Water Testing

- AUTOMATIC TITRATORS

- Thermal Analysis

- Automatic Kjeldahl Analyzer

- TOC Analyzer

- Universal Testing Machine

- Price List of Reagents

- Fluorescence Spectrometer

- NIR Spectrophotometer

LATEST NEWS

CONTACT US

Contact: Harry

Phone: 00852-82283663

E-mail: info@lab-kits.com

Add: ROOM 1, 16F, EMPRESS PLAZA, 17-19 CHATHAM ROAD, TSIM SHA TSUI, KOWLOON, HONG KONG