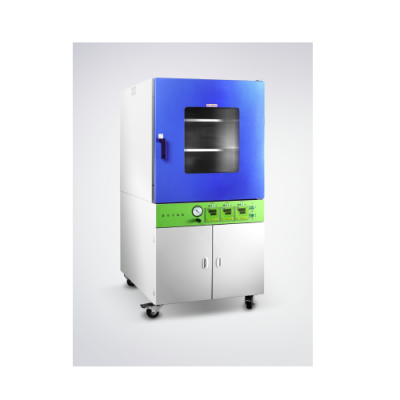

High Temperature Sintering Furnace

Product ID:151B

The new generation of 151B series High Temperature Sintering Furnace absorbs advanced foreign technology while reserving the original functions. It innovates greatly on appearance and performance, the modeling is more beautiful and the structure is more reasonable. Its new style and advantage of energy-saving can compare favorably with the same products abroad. The instrument adopts the advanced LTDE modularized structure, the programmable control system is with strong programming and operation ability, it can set 30-section program arrangement and the rise, drop slope of any given value, and the position machine application software can be selected according to requirements, which is with the functions such as data timing preservation and printing, RS-232/RS-485 converter can be selected to connect the computer for remote control and record of the temperature, thus make it possible to repeat any test in the same way.

The outer plate of the furnace is made of high quality cold-rolled sheets which are treated with antirust and high temperature plastic spraying, the inner is made of stainless steel sheet, the heat preservation material is alumina silicate wool; it adopts foreign imported point distribution forced convection technology, thus makes the temperature in the furnace reach the same effect with no turntable, and utilizes the available space in the furnace to the maximum, the work efficiency is three times or above higher than the original! The high quality stainless steel heating tube is easy to operate and maintain; the instrument is equipped with overheat protection relay, fuse, electric shock protector and super-temperature protection device, making it safe and reliable; the pole-type alarm device makes lighting alarm automatically when the temperature rises, becomes constant upon the work of instrument, and the work finishes, which greatly facilitates the operation of personnel. It is applicable to factories and scientific research units for the sintering of compressed molding products such as tetrafluoroethylene, trifluoroethene etc., as well as rubber with plastic molecules, plastic etc.; the high temperature heat aging test of the electric insulation and other materials as well as welding wire etc. are suitable for high temperature melting, drying treatment.

Technical parameters:

Name | High Temperature Sintering Furnace | |||

Type | 151B-1 | 151B-2 | 151B-3 | 151B |

Temperature range | 50-500℃ | |||

Temperature fluctuation | ±1℃ | |||

Temperature evenness in available space | ≤±1.5% | |||

Rated power | 2500W | 3500W | 4500W | 7500W |

Voltage | 220V 50HZ | 380 50HZ | ||

Number of shelf layers | Two layers, distance between the shelves is adjustable | |||

Average load of each layer | ≥5KG | ≥10KG | ≥15KG | ≥25KG |

Temperature control mode | LTDE programmable instrument PID, tracking alarm | |||

Timing period | 9999min | |||

Temperature sensor | Grade K mark thermocouple | |||

Circulation mode | Point distribution forced hot air circulation | |||

Heating components and mode | High temperature heating chamber, gear running balance air wheel | |||

Air vent | At back | On top | ||

Heater | Stainless steel heating tube | Stainless steel heating tube, heating wire | ||

Safety device | Safety door lock, electric shock switch, leakage switch, overload protection, fuse, and two-grade over-temperature protection | |||

Working dimensions | 350*450*450 | 450*550*550 | 500*600*750 | 800*800*1000 |

INQUIRY

CATEGORIES

- Coal Testing

- Petroleum Testing

- Muffle Furnace

- Highway Instruments

- Direct Reading Spectrometer

- Abbe & Auto Refractometer

- Agricultural Instruments

- Autoclave/Sterilizer

- Weighting Balance & Scales

- Safety Cabinet & Clean Bench

- Carbon & Sulfur Analyzer

- Centrifuge

- Clinical Instruments

- Colorimeter & Color Light Box

- Dehumidifier & Humidifier

- Electrolyte Analyzer

- Electrophoresis Cell

- Freeze Dryer

- Gas Generator

- Gene Test

- Heating & Drying Oven

- Pathology Instruments

- Ice Maker

- ICP Spectrometers

- Incubators

- Infrared Thermometer

- Freezer & Refrigeration Products

- Liquid Nitrogen Container

- Biological Microscope

- Microwave Digestion & Extraction

- Mixer & Homogenizer

- Mixer & Shaker

- Moisture Analyzer

- Moisture Tester

- Oil-in-Water Analyzer

- Pack & Paper Testing

- Automotive teaching model

- Particle Counter

- Plastic Testing

- Particle Size Analyzer

- Polarimeter & Saccharimeter

- Rotary Evaporator

- Sampling Instruments

- Small Instruments

- Spectrophotometer

- Water Purifier

- Water quality detector

- XRF

- Water Testing

- AUTOMATIC TITRATORS

- Thermal Analysis

- Automatic Kjeldahl Analyzer

- TOC Analyzer

- Universal Testing Machine

- Price List of Reagents

- Fluorescence Spectrometer

- NIR Spectrophotometer

LATEST NEWS

CONTACT US

Contact: Harry

Phone: 00852-82283663

E-mail: info@lab-kits.com

Add: ROOM 1, 16F, EMPRESS PLAZA, 17-19 CHATHAM ROAD, TSIM SHA TSUI, KOWLOON, HONG KONG