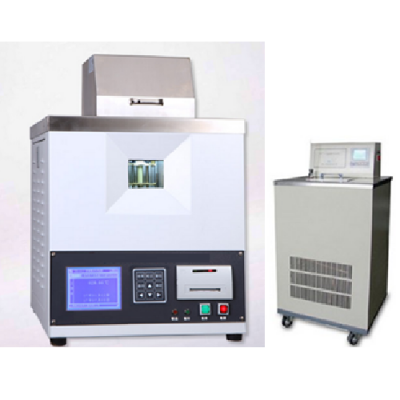

Asphalt Mixture Shearing Compactor

Product ID:HW-SYD-7981

This equipment is designed and manufactured in accordance with ASTM D7981-2015 Standard Practice for Compaction of Prismatic Asphalt Specimens by Means of the Shear Box Compactor. New equipment developed by cutting-edge technology for forming and compacting mixture samples.

This equipment uses shear compaction molding technology to make asphalt mixture specimens. During the molding process, the two side walls of the test mold move horizontally so that the mixture is subjected to shearing force, while the vertical direction applies a load to the specimen. Under the action, an ideal specimen with regular aggregate arrangement and uniform density distribution is obtained.

Main technical features

1. The quality of the molded test piece is excellent, which overcomes the uneven force of the upper and lower layers of the fan-shaped rolling molding, the rotary compaction molding is formed one piece at a time, and there are differences between different test pieces, the compaction molding is formed one piece at a time and the test piece is uneven And other issues.

2. The length, width, and height dimensions of the molded test piece are 450mm×150mm×(120~185mm), one test piece can be cut into (4~6) prism/trabecular bending test pieces, or can be drilled (1~4) Cylindrical specimens, or cutting and drilling other required specimens, all cut or drilled specimens have good consistency, the test results are reliable, and the comparison test is scientific and reasonable.

3. This equipment has multiple functions in one machine, and is equipped with our company's asphalt mixture cutting machine and asphalt mixture multi-function coring machine, and you can obtain asphalt of various specifications in the JTG-E20 "Highway Engineering Asphalt and Asphalt Mixture Test Regulations" Mixed material specimens, and the quality of the specimens is better, and the test results are more accurate.

4. Using high-hardness and high-quality steel frame structure, the instrument is firm and stable, and has good dynamic stability.

5. The horizontal shearing action is controlled by a high-precision servo motor, and the shearing angle is continuously adjustable, up to 4°.

6. Display real-time data, including shear force, compressive strength, specimen height, and display compaction curve, while saving related parameters.

7. Use special mold testing and loading tools to ensure uniform loading distribution; the test piece can be automatically demolded after molding.

Main technical parameters and indicators

1. Power supply (reference): AC220V/50Hz, 5000

2. Maximum shear angle: 4°

3. Frequency: 3.7 cycles/minute

4. Maximum contact pressure: 2MPa

5. Compaction density: controllable density during molding

INQUIRY

CATEGORIES

- Coal Testing

- Petroleum Testing

- Muffle Furnace

- Highway Instruments

- Direct Reading Spectrometer

- Abbe & Auto Refractometer

- Agricultural Instruments

- Autoclave/Sterilizer

- Weighting Balance & Scales

- Safety Cabinet & Clean Bench

- Carbon & Sulfur Analyzer

- Centrifuge

- Clinical Instruments

- Colorimeter & Color Light Box

- Dehumidifier & Humidifier

- Electrolyte Analyzer

- Electrophoresis Cell

- Freeze Dryer

- Gas Generator

- Gene Test

- Heating & Drying Oven

- Pathology Instruments

- Ice Maker

- ICP Spectrometers

- Incubators

- Infrared Thermometer

- Freezer & Refrigeration Products

- Liquid Nitrogen Container

- Biological Microscope

- Microwave Digestion & Extraction

- Mixer & Homogenizer

- Mixer & Shaker

- Moisture Analyzer

- Moisture Tester

- Oil-in-Water Analyzer

- Pack & Paper Testing

- Automotive teaching model

- Particle Counter

- Plastic Testing

- Particle Size Analyzer

- Polarimeter & Saccharimeter

- Rotary Evaporator

- Sampling Instruments

- Small Instruments

- Spectrophotometer

- Water Purifier

- Water quality detector

- XRF

- Water Testing

- AUTOMATIC TITRATORS

- Thermal Analysis

- Automatic Kjeldahl Analyzer

- TOC Analyzer

- Universal Testing Machine

- Price List of Reagents

- Fluorescence Spectrometer

- NIR Spectrophotometer

LATEST NEWS

CONTACT US

Contact: Harry

Phone: 00852-82283663

E-mail: info@lab-kits.com

Add: ROOM 1, 16F, EMPRESS PLAZA, 17-19 CHATHAM ROAD, TSIM SHA TSUI, KOWLOON, HONG KONG