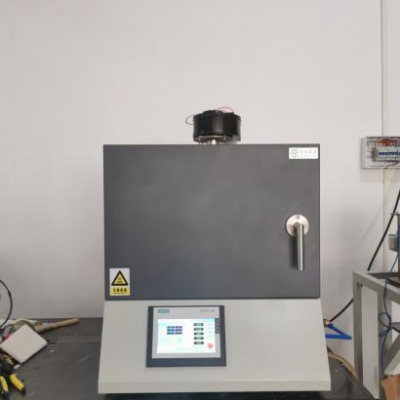

Vacuum atmosphere furnace

Product ID: LYL-17ZK, LYL-17Z, LYL-18ZK

Equipment widely used in universities, research institutes, industrial and mining enterprises such as powder, military, electronics, metallurgy, medicine, ceramics, glass, machinery, new material development, special materials, refractory materials, building materials, chemicals, metal sintering and metal heat treatment experiment and production.

Technical characteristics

1. This equipment introduces foreign advanced technology, self-developed and produced high-efficiency, energy-saving, environmental protection, new electric furnace, with advanced and reasonable structure, beautiful appearance, high-quality cold-rolled steel plate, advanced CNC machine tool processing, luxury, beautiful two-color import epoxy powder electrostatic spray process, processed, high temperature resistance, corrosion resistance, long-term non-fading; using high-quality heating elements, the furnace has a warm field balance, the furnace surface temperature is low, the rise, insulation, cooling rate can be arbitrarily adjusted, energy saving and other advantages;

2. The furnace is made of ceramic fiber material through unique numerical control technology. It has strong thermal shock resistance, strong resistance to rapid cooling and heat good corrosion resistance, no collapse, no crystallization, no slag, no pollution, long service life; the control system adopts computer artificial intelligence adjustment technology, with PID adjustment, automatic control, self-tuning function, multi-stage program programming, and can prepare various heating, heat preservation and cooling programs with high temperature control precision; Integrated module thyristor control, phase shift triggering; protection system: independent over-temperature protection, over-pressure, over-current, leakage, short-circuit protection, etc., high degree of automation, all indicators have reached the international advanced level;

3. It can be vacuumed and has a variety of gases. The valve is equipped with and intake valve, and exhaust valve and a vacuum valve. It can pass a variety of gases: argon, nitrogen, oxygen, vacuum system with multi-stage O-type seal, the heat-resistant rubber pad ensures reliable sealing, small vacuum leakage, and the pressure inside the furnace is displayed by the meter. It is easy to operate with vacuum interface conditions.

Additional configuration

1. In addition, through the control software independently developed by our company, the electric furnace is connected with the computer, which can realize remote control of single or multiple electric furnaces, start electric furnace, stop electric power, set temperature control program, store temperature control program, view historical curve, printing history curves, etc.

2. The mass flow meter accurately displays the gas flow and is programmable to automatically control the gas flow

3. Molecular pumps, diffusion pumps, roots pumps, mechanical pumps can meet a variety of vacuum requirements

4. The digital vacuum gauge displays the vacuum with high precision.

Furnace size

Crucible volume (L) | Voltage (V) | Power (kw) | Temperature control accuracy |

200*150*150 | 220 | 4 | ± 1 ℃ |

300*200*200 | 380 | 10 | ± 1 ℃ |

400*300*300 | 380 | 14 | ± 1 ℃ |

500*300*300 | 380 | 18 | ± 1 ℃ |

Temperature: 800 ℃,1000 ℃,1200 ℃,1400 ℃,1600 ℃ 1700 ℃ | |||

l Chamber size and temperature according to customer need;

l Control system: computer control, touch screen control, micro-computer control can be optional;

l Vacuum system and atmosphere system can be configured according to customer requirements;

l Gas control: rotor flow meter, mass digital flow meter optional.

INQUIRY

CATEGORIES

- Coal Testing

- Petroleum Testing

- Muffle Furnace

- Highway Instruments

- Direct Reading Spectrometer

- Abbe & Auto Refractometer

- Agricultural Instruments

- Autoclave/Sterilizer

- Weighting Balance & Scales

- Safety Cabinet & Clean Bench

- Carbon & Sulfur Analyzer

- Centrifuge

- Clinical Instruments

- Colorimeter & Color Light Box

- Dehumidifier & Humidifier

- Electrolyte Analyzer

- Electrophoresis Cell

- Freeze Dryer

- Gas Generator

- Gene Test

- Heating & Drying Oven

- Pathology Instruments

- Ice Maker

- ICP Spectrometers

- Incubators

- Infrared Thermometer

- Freezer & Refrigeration Products

- Liquid Nitrogen Container

- Biological Microscope

- Microwave Digestion & Extraction

- Mixer & Homogenizer

- Mixer & Shaker

- Moisture Analyzer

- Moisture Tester

- Oil-in-Water Analyzer

- Pack & Paper Testing

- Automotive teaching model

- Particle Counter

- Plastic Testing

- Particle Size Analyzer

- Polarimeter & Saccharimeter

- Rotary Evaporator

- Sampling Instruments

- Small Instruments

- Spectrophotometer

- Water Purifier

- Water quality detector

- XRF

- Water Testing

- AUTOMATIC TITRATORS

- Thermal Analysis

- Automatic Kjeldahl Analyzer

- TOC Analyzer

- Universal Testing Machine

- Price List of Reagents

- Fluorescence Spectrometer

- NIR Spectrophotometer

LATEST NEWS

CONTACT US

Contact: Harry

Phone: 00852-82283663

E-mail: info@lab-kits.com

Add: ROOM 1, 16F, EMPRESS PLAZA, 17-19 CHATHAM ROAD, TSIM SHA TSUI, KOWLOON, HONG KONG