Electric-heating freeze dryer

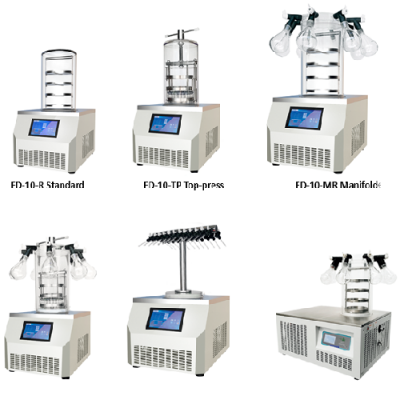

Product ID:FD-10F-R, FD-10F-TP, FD-30F-ER, FD-50F-ER

This series of freeze dryers with electric heating function (patent machine). Products can be freeze dried in situ. It changes the complex operation and prevent sample pollution, and make drying automation. These models have shelf heating and programmable functions. They can records freeze drying curves; data can be output by U-disk. User can clearly view the freeze-drying process.

Features

The company's patented product square warehouse in situ vacuum freeze dryer, pre-freezing, drying in situ completed, easy to operate, good drying effect.

The drying chamber door is made of ACRYLIC material, which is colorless, transparent and can observe the whole process of freeze-drying.

The inflatable (drainage) valve adopts safety diaphragm valve, which can connect inert gas source, fill inert gas after drying, and prolong the shelf life of materials.

Specialized gas diversion technology, uniform cold trap ice capture, ice capture ability.

International well-known brand compressor, high efficiency and energy saving, long service life, low noise.

The patented technology of partition and the fuzzy control technology of partition temperature have the advantages of small temperature difference of shelf, high precision of temperature control and even drying effect.

Powerful sensor calibration function ensures long-term use of measurement accuracy.

7-inch real-color industry embedded touch screen + SH-HPSC-II modular controller, high control accuracy, stable and reliable performance.

The specially designed FD-EMB control system can preserve hundreds of formulations, each of which contains 50 temperature control sections, so as to improve the process optimization rate.

Intelligent data recording system can record and display the temperature curve of cold trap, sample temperature curve and vacuum curve in real time. The derived data can be browsed and printed by computer and operated in a variety of ways to facilitate process optimization and drying effect verification.

Flexible manual + automatic control mode, manual for exploring process, automatic for batch production.

Real-time alarm display and historical alarm inquiry functions facilitate fault diagnosis and equipment maintenance.

User level and password can be set, and operation management can be decentralized.

Optional accessories and functions

Cold trap temperature -80℃

Eutectic point tester

Vacuum pump anti-return device

Cold trap electric heating defrosting

Oil mist filtration system

Vacuum regulating system

LYO-MEGA Software System

Mobile App Monitoring System

Backfill filter

Eggplant bottle device

International brand vacuum pump

Non-standard customization

Technical index

Model | Unit | FD-10F-R Standard | FD-10F-TP Top-press | FD-30F-ER Standard | FD-50F-ER Standard | |||||

Freeze-drying area | ㎡ | 0.2 | 0.1 | 0.4 | 0.6 | |||||

Cold trap temperature | ℃ | < -60 (no-loading), option < -80 (no-loading) | ||||||||

Vacuum degree | Pa | ≤ 5 (no-loading) | ||||||||

Shelf temp range | ℃ | -50-+70 (no-load) | ||||||||

Water-capture capability | kg/24h | ≥ 6 | ≥ 8 | ≥ 10 | ||||||

Tray dimension | mm | 265×395 | 265×395 | 295×335 | 295×335 | |||||

Trays number | pc | 2 | 1 | 4 | 6 | |||||

Shelf size | mm | 270×400 | 270×400 | 300×340 | 300×340 | |||||

Shelf spacing | mm | 70 | 50 | 50 | ||||||

Power | w | 2000 | 2700 | 4500 | ||||||

Weight | kg | 210 | 280 | 450 | ||||||

Dimension | mm | 655×640×1200 | 890×660×1210 | 890×670×1470 | ||||||

Bulk capacity (thickness 10mm) | L | 2 | 1 | 4 | 6 | |||||

Vial loading number | piece | - | Ф12mm:777 | - | - | |||||

piece | - | Ф16mm:434 | - | - | ||||||

piece | - | Ф22mm:220 | - | - | ||||||

Defrosting | - | Natural defrosting (option electric defrosting) | ||||||||

Power | - | 1Ph + N + PE, 220V | 1Ph + N + PE, 220V | 3 phases + N + PE, 38 | ||||||

INQUIRY

CATEGORIES

- Coal Testing

- Petroleum Testing

- Muffle Furnace

- Highway Instruments

- Direct Reading Spectrometer

- Abbe & Auto Refractometer

- Agricultural Instruments

- Autoclave/Sterilizer

- Weighting Balance & Scales

- Safety Cabinet & Clean Bench

- Carbon & Sulfur Analyzer

- Centrifuge

- Clinical Instruments

- Colorimeter & Color Light Box

- Dehumidifier & Humidifier

- Electrolyte Analyzer

- Electrophoresis Cell

- Freeze Dryer

- Gas Generator

- Gene Test

- Heating & Drying Oven

- Pathology Instruments

- Ice Maker

- ICP Spectrometers

- Incubators

- Infrared Thermometer

- Freezer & Refrigeration Products

- Liquid Nitrogen Container

- Biological Microscope

- Microwave Digestion & Extraction

- Mixer & Homogenizer

- Mixer & Shaker

- Moisture Analyzer

- Moisture Tester

- Oil-in-Water Analyzer

- Pack & Paper Testing

- Automotive teaching model

- Particle Counter

- Plastic Testing

- Particle Size Analyzer

- Polarimeter & Saccharimeter

- Rotary Evaporator

- Sampling Instruments

- Small Instruments

- Spectrophotometer

- Water Purifier

- Water quality detector

- XRF

- Water Testing

- AUTOMATIC TITRATORS

- Thermal Analysis

- Automatic Kjeldahl Analyzer

- TOC Analyzer

- Universal Testing Machine

- Price List of Reagents

- Fluorescence Spectrometer

- NIR Spectrophotometer

LATEST NEWS

CONTACT US

Contact: Harry

Phone: 00852-82283663

E-mail: info@lab-kits.com

Add: ROOM 1, 16F, EMPRESS PLAZA, 17-19 CHATHAM ROAD, TSIM SHA TSUI, KOWLOON, HONG KONG