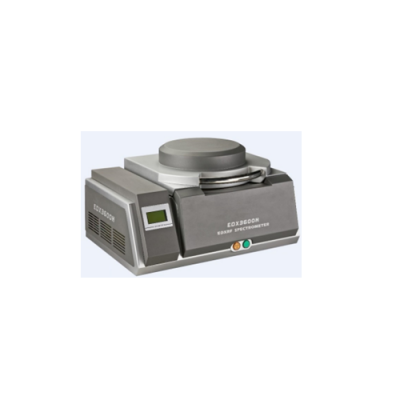

X-ray Fluorescence Sulfur Detector

X-ray Fluorescence Sulfur Detector

Model ID: EDX3300S

Description

Nowadays, controlling the sulfur content in petrochemical products, especially 1n oil products (such as gasoline, diesel, lubricating oil, etc.) has become the focus of environmental protection worldwide. When oil with high sulfur content is combust, carbon dioxide will be generated and then be cooled to generate water. Water and sulfur are combined to generate sulfurous acid or sulfuric acid which will corrode the engine. When large amount of sulfur oxides get into air, air pollution can be caused, including forming acid rain. Excessive sulfate will be formed after the sulfur in gasoline is combusted, and will be attached to the precious metal coating surface of the catalyst, resulting in excessive emissions of automobile exhaust. Therefore, it is very important to reduce the sulfur content in gasoline .

EDX 3300S X-ray Fluorescence Sulfur Detector is more efficient and intelligent than EDX 3200S PLUS which is previously launched. The instrument complies with national standards, including the Limits and measurement methods for emissions from light-duty vehicles (CHINA 5), GB252-2015 , GB/T17040-2008 ,etc., and international standards , including ASTM 7039 and so on.

Application:

Petrochemical engineering, crude oil exploration and refining, liquid element analysis, refined oil, refinery product line monitoring.

Performance advantages:

Small and exquisite appearance, simple and integrated design equipped with integrated computer, can be used in both vehicles and laboratories , easy to use.

Vacuum system with no need to fill with helium, reducing test costs .

Ultra- short test distance, improving the precision of tested samples.

Down-lighting design, avoiding light tube and beryllium window being contaminated by sample volatilization ; capable of measuring light oil such as gasoline and diesel, and improving measurement precision.

High excitation efficiency side-window, high-power X-ray tube, most advanced SDD detector , and good heat dissipation ensure the

high efficiency and stability of the test.

Automatic calibration after power on, ensuring consistent test precision.

Intelligent sulfur measuring and analyzing software , one-click operation, intelligent algorithm equipped for detecting low-content sulfur, high-content sulfur and different oil, no need to manually select curves, reducing test error resulted from manual curve selection.

X-ray shielded design for safe operation.

Technical Parameters:

Analyzed Element: S, Cl

Analysis Range: 1ppm-20%

Limit of Detection: 1ppm

Function: Special for petroleum element analysis

Integrated PC: 1O" industrial tablet PC

Analytical Precision: 1Oppm, the precision can be controlled to <10% Measuring Time: 200-600S

Measuring Object: Liquid, Solid, Powder

Working Voltage: AC110V/220V

Working Temperature: 10-35 °C

Dimension: L/W/H< 400mm, Volume: 0.06m' (can be mounted on vehicle) Weight: <30kg

INQUIRY

CATEGORIES

- Coal Testing

- Petroleum Testing

- Muffle Furnace

- Highway Instruments

- Direct Reading Spectrometer

- Abbe & Auto Refractometer

- Agricultural Instruments

- Autoclave/Sterilizer

- Weighting Balance & Scales

- Safety Cabinet & Clean Bench

- Carbon & Sulfur Analyzer

- Centrifuge

- Clinical Instruments

- Colorimeter & Color Light Box

- Dehumidifier & Humidifier

- Electrolyte Analyzer

- Electrophoresis Cell

- Freeze Dryer

- Gas Generator

- Gene Test

- Heating & Drying Oven

- Pathology Instruments

- Ice Maker

- ICP Spectrometers

- Incubators

- Infrared Thermometer

- Freezer & Refrigeration Products

- Liquid Nitrogen Container

- Biological Microscope

- Microwave Digestion & Extraction

- Mixer & Homogenizer

- Mixer & Shaker

- Moisture Analyzer

- Moisture Tester

- Oil-in-Water Analyzer

- Pack & Paper Testing

- Automotive teaching model

- Particle Counter

- Plastic Testing

- Particle Size Analyzer

- Polarimeter & Saccharimeter

- Rotary Evaporator

- Sampling Instruments

- Small Instruments

- Spectrophotometer

- Water Purifier

- Water quality detector

- XRF

- Water Testing

- AUTOMATIC TITRATORS

- Thermal Analysis

- Automatic Kjeldahl Analyzer

- TOC Analyzer

- Universal Testing Machine

- Price List of Reagents

- Fluorescence Spectrometer

- NIR Spectrophotometer

LATEST NEWS

CONTACT US

Contact: Harry

Phone: 00852-82283663

E-mail: info@lab-kits.com

Add: ROOM 1, 16F, EMPRESS PLAZA, 17-19 CHATHAM ROAD, TSIM SHA TSUI, KOWLOON, HONG KONG