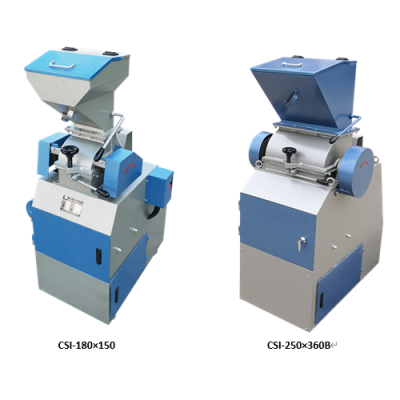

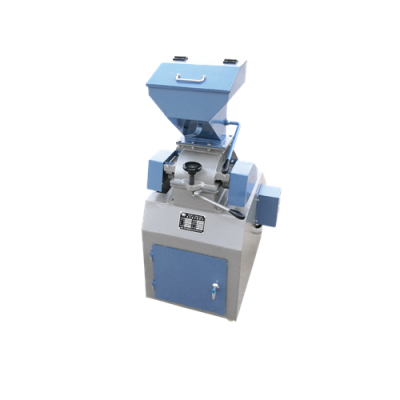

Sealed Hammer cutter Crusher (Without Splitting/Reduction Facility)

Sealed Hammer cutter Crusher (Without Splitting/Reduction Facility)

Order No.: CSI-D150/ CSI-D80

Summary:

This product is based on the advanced technology of sampling equipment, which is the new product developed according to GB474《preparation method of coal sample》, GB/T18666 《commercial coal quality inspection and acceptance method》, etc. It is mainly applied to coal, electricity, metallurgy, chemical engineering, environmental protection, geology, scientific research, etc.

Main feature:

1.Totally sealed, no dust pollution, and conforming to the environmental protection requirement.

2.The crushing cavity is made of steel. wear proof and durable, effectively preventing sample being polluted and over heat.

3.The hammer cutter material is Ni-WC35 ni-based tungsten carbide coated, which is of high strength and durableness. Could crush ore material of high strength and high hardness, such as coke, metal lump ore, pellet, etc.

4.The hammer is in symmetrical and cambered design, prolonging the service life of hammer cutter.

5. can crush the materials by whole section. The cavity will not be plugged. There is no phenomenon of dead ends depositing sample.

6.It can complete the crushing, mixing and separating rapidly, significantly improve the efficiency and will not lose moisture.

7.It is very convenient to operate, maintain and clean.

8.Operate steadily with low noise.

9.All driving components have protective facilities, meeting safety requirements of production.

Main technical parameters:

Model | CSI-D150 | CSI-D80 | |

Feeding size | ≤150mm | ≤80mm | |

Output size | <13、<6 (adjustable) | <6、<3 (adjustable) | |

Productivity | 3000-1800Kg/h | 1800-1200Kg/h | |

Weight | 480kg | 300kg | |

Dimensions | 1100×800×1500mm | 930×630×1330mm | |

Motor power | 5.5kw | 4kw | |

Working Power | Three-Phase 380V | ||

Rotor form | Ni-WC35 ni-based tungsten carbide coated hammer cutter | Ni-WC35 ni-based tungsten carbide coated hammer cutter | |

INQUIRY

CATEGORIES

- Coal Testing

- Petroleum Testing

- Muffle Furnace

- Highway Instruments

- Direct Reading Spectrometer

- Abbe & Auto Refractometer

- Agricultural Instruments

- Autoclave/Sterilizer

- Weighting Balance & Scales

- Safety Cabinet & Clean Bench

- Carbon & Sulfur Analyzer

- Centrifuge

- Clinical Instruments

- Colorimeter & Color Light Box

- Dehumidifier & Humidifier

- Electrolyte Analyzer

- Electrophoresis Cell

- Freeze Dryer

- Gas Generator

- Gene Test

- Heating & Drying Oven

- Pathology Instruments

- Ice Maker

- ICP Spectrometers

- Incubators

- Infrared Thermometer

- Freezer & Refrigeration Products

- Liquid Nitrogen Container

- Biological Microscope

- Microwave Digestion & Extraction

- Mixer & Homogenizer

- Mixer & Shaker

- Moisture Analyzer

- Moisture Tester

- Oil-in-Water Analyzer

- Pack & Paper Testing

- Automotive teaching model

- Particle Counter

- Plastic Testing

- Particle Size Analyzer

- Polarimeter & Saccharimeter

- Rotary Evaporator

- Sampling Instruments

- Small Instruments

- Spectrophotometer

- Water Purifier

- Water quality detector

- XRF

- Water Testing

- AUTOMATIC TITRATORS

- Thermal Analysis

- Automatic Kjeldahl Analyzer

- TOC Analyzer

- Universal Testing Machine

- Price List of Reagents

- Fluorescence Spectrometer

- NIR Spectrophotometer

LATEST NEWS

CONTACT US

Contact: Harry

Phone: 00852-82283663

E-mail: info@lab-kits.com

Add: ROOM 1, 16F, EMPRESS PLAZA, 17-19 CHATHAM ROAD, TSIM SHA TSUI, KOWLOON, HONG KONG